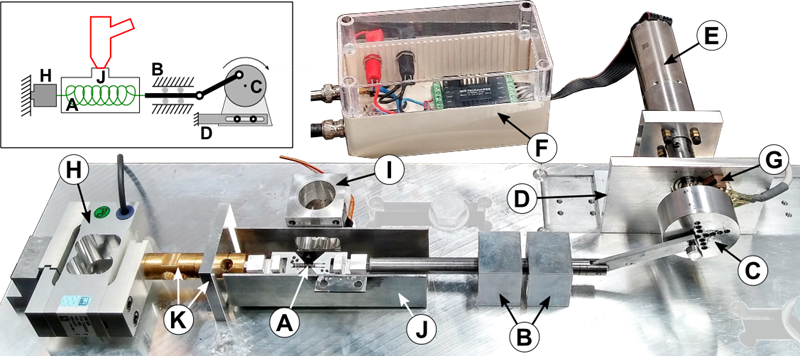

Springs made from a shape memory alloy are characterized in terms of their force-deflection behaviour at different environmental temperatures. Shape memory alloy springs are non-linear and have a strong thermo-mechanical coupling. This means that it is important to known exactly the environmental temperature, the loading rate and the level of pretension. These properties can be adjusted in the test bench. The environmental temperature is accurately controlled using a heat chamber, a modified heat gun and a thermocouple.

|

| Tensile test-bench. (A) SMA spring, (B) linear ball bearings holding the piston arm, (C) crank wheel that controls the deflection amplitude, (D) slider that determines the pretension length, (E) brushless DC motor controlling speed, (F) motor controller, (G) encoder measuring crank wheel angle and speed, (H) force transducer measuring spring force, (I) heat gun inlet and thermocouple, (J) heat chamber (shown without its lid), (K) heat wall and arm. |